Eurofighter generator test bench

Machines as complex as aircraft incorporate electrical power systems for the operation of some of their equipment and processes.

These engines have to meet a number of technical requirements during operation and are therefore subjected to all kinds of tests on so-called test benches.

As these benches, where high sound pressure levels are generated, are located next to other installations that may be affected, it is necessary to control their acoustic and vibration impact.

In this project we have carried out a complete acoustic treatment for one of these test benches. The installation carried out includes the following parts:

Floating bed.

This is a fundamental part of the installation, as it will radically reduce the vibration transmissions generated by the equipment during the tests. In this case, a reinforced concrete slab has been built on Acustilástic-N damping material.

Acoustic insulation ceiling.

It includes a floating system made up of a framework of elastic supports and fastening profiles, absorbent filling of the air chamber and a multilayer system based on plasterboard panels and specific insulating materials to increase the performance of the whole. With this system we manage to improve the airborne sound insulation of the existing slab.

Large format acoustic door.

In this case, due to the dimensions of the motors and the auxiliary means for their displacement, a large-format RS3-XL acoustic door was installed for access to the test room. Thanks to the incorporation of a removable lower frame, the door allows maximum functionality without losing its high level of acoustic insulation.

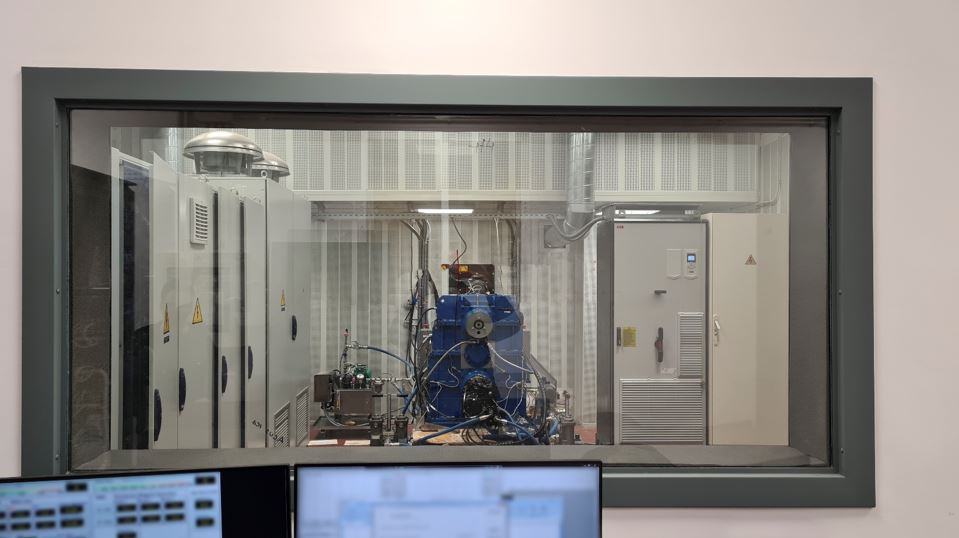

Acoustic control viewer.

In order to maintain direct visual contact and to allow the technicians to monitor the tests from the control room annexed to the test bench, a large-format VR type acoustic viewer was installed in the partition wall between the two enclosures.

This type of viewers, consisting of two independent frames with laminated glass of high insulation and mechanical strength, ensures that there is no loss of sound insulation between the two rooms.

Absorbent acoustic treatment on ceiling and walls.

To finish, the ceiling and walls of the room were treated with Acustison-50A absorber panels.

This type of acoustic panels is especially recommended for rooms such as this test bench. On the one hand, they provide a high absorption capacity over a wide frequency range. On the other hand, the mechanical strength of the material makes it ideal for use in industrial environments.

It should be noted that the engine under test is an alternating current generator. This means that no combustion gases are generated during the tests as in other types of engines.

Ventilation is ensured by circular ducts that connect the inside of the bench with the outside, generating airflow through an extraction motor.

Acústica Integral can help you to set up your laboratory or test bench. If you need our help to carry out your project, contact us.

Contact Acústica Integral